3D printing for research

We have just received funding from MMU to allow us to buy a 3D printer for research. I am exploring the use of this disruptive technology in my own environmental microbiology research, and am collaborating with other researchers who are interested in applying it in other projects including bryophyte photosynthesis and wearable technology for humans and animals.

I wrote an earlier post about reproducible research, but really it only talked about a reproducible analysis. With the advent of 3D printing it is becoming easier to make experimental work reproducible too. 3D printing and the internet mean that research publications can now include custom apparatus designs more easily than ever before which I think will be very beneficial if it becomes widely adopted:

- Avoid duplication of development tasks in different labs

- More chance of results being verified and extended independently

- Less reliance on proprietary devices in research (cost benefit and “know how it works” benefit)

- Availability of research equipment to less well off labs

- Drive innovation by technology companies (innovate or perish)

- etc.

The lab and recent book of Joshua Pearce demonstrate a lot of the basic workflow I want to adopt in research, and are good sources for anyone looking into this.

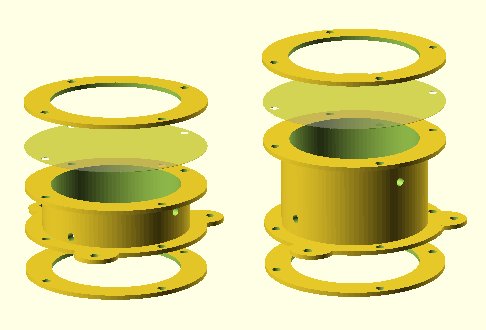

I want to use an open research workflow for my current project which is to do with measuring carbon dioxide emission and absorption by soil. I have already developed a laboratory microcosm system and performed experiments on Kalahari soils which I am preparing to publish. The hardware was largely hand-made though and will not be easy for others to replicate or adopt, which reduces the value of the paper. I am now planning some follow-up work which will use a similar experimental system but with an extra emphasis on ease of use for other researchers.

In a previous post I discussed 3D software for the open source workflow. Having our own printer will be very useful for development of designs, however it is not a prerequisite for taking advantage of 3D printing because there are many companies offering 3D printing services.